Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

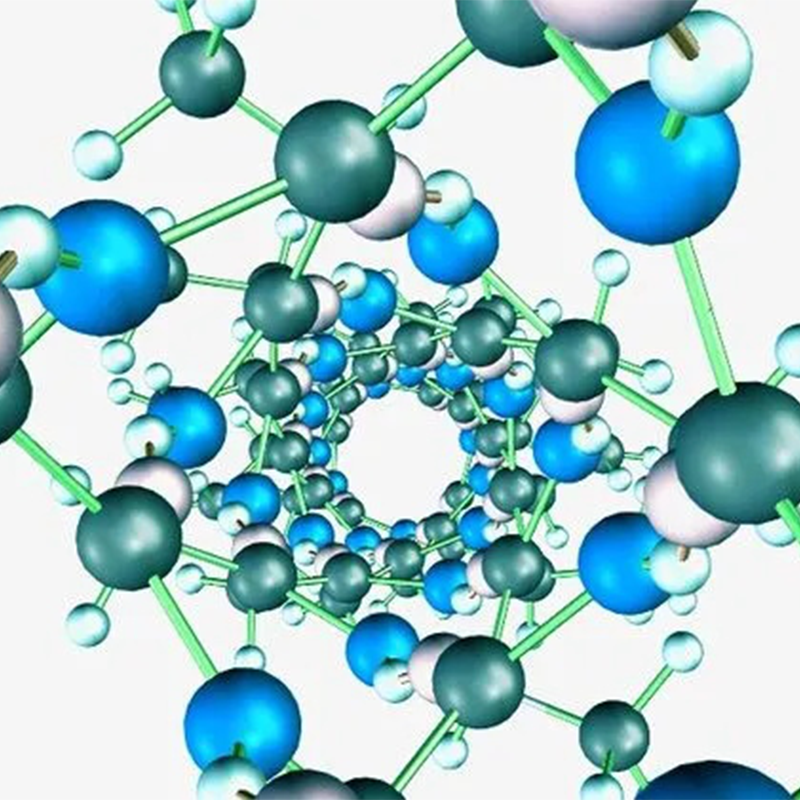

New Series of RIM-DCPD material,Compared with tungsten-molybdenum series, ruthenium-based DCPD was improved with three characteristics: 1. Ruthenium-based DCPD does not need nitrogen protection as it's less sensitive to water and oxygen; 2. It's easy to control the speed of the polymerization reaction, with richer process control performance and better product surface smooth effect, 3. The polymerization reaction leads to less by-reaction, catalyst more specific. More kinds of dyes, flame retardants and other modifiers without affecting the properties of the materials can be added.

Our revolutionary ruthenium-based DCPD material sets a new standard in the industry, offering unparalleled benefits and versatility. Unlike traditional materials, our product eliminates the need for nitrogen protection, simplifying the manufacturing process and reducing costs. The precise control over the polymerization reaction speed ensures consistent and high-quality results, while the reduced by-reaction minimizes waste and enhances efficiency.

Moreover, our material’s compatibility with various modifiers allows for endless customization possibilities without compromising its exceptional properties. Designers can unleash their creativity and achieve unique product designs with ease. The smooth surface finish achieved with our ruthenium-based DCPD material adds a touch of sophistication to any application.

Enhanced Chemical and Water Resistance: The ruthenium-based DCPD material offers superior resistance to chemicals and water, making it ideal for applications where durability and longevity are essential.

High Impact Strength: With its high impact strength, this material can withstand tough conditions and heavy use without compromising its structural integrity.

Reduction in Total Number of Parts: By using ruthenium-based DCPD material, manufacturers can reduce the total number of parts required for a product, simplifying assembly processes and reducing overall production costs.

Design Flexibility and Economic Benefits: This material provides a high degree of design flexibility, allowing for the creation of complex shapes and openings with ease. Additionally, the significant economic benefits, such as lower molding equipment costs, make it a cost-effective solution for various applications.

|

Application Area |

Features |

|

Chemical Pipelines |

|

|

Unmanned Surface Vessels - Carbon Fiber Composites |

/ |

|

Drones - Carbon Fiber Composites |

/ |